Keeping knives sharp is important; it helps with ease of cutting, and more importantly, it prevents accidents. If you’re using a dull knife, the blade is more likely to slip off the cutting surface and create an accident. There are several different ways to sharpen a knife; I’ll go over a few here.

First of all, make sure that you have a good knife- something made of forged stainless steel. What is forged stainless steel?

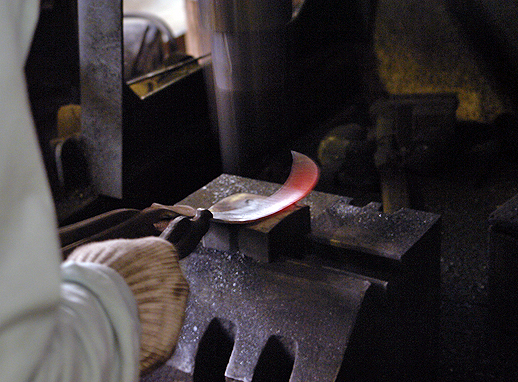

Forging is the process by which metal is heated and is shaped by plastic deformation by suitably applying compressive force. Usually the compressive force is in the form of hammer blows using a power hammer or a press.

Forging refines the grain structure and improves physical properties of the metal. With proper design, the grain flow can be oriented in the direction of principal stresses encountered in actual use. Grain flow is the direction of the pattern that the crystals take during plastic deformation. Physical properties (such as strength, ductility and toughness) are much better in a forging than in the base metal, which has, crystals randomly oriented.

Source: http://www.efunda.com/processes/metal_processing/forging.cfm

Plain steel knives rust, and the blade quickly loses its structure. The metal breaks down, resulting in chips, cracks, and even fractures. Always use a stainless steel knife.

Most good knives come sharpened, however over time the edge of the blade becomes dull due to use. If your knife becomes only slightly dull, it’s time to sharpen it.

Remember: A sharpening steel does NOT create an edge, it only maintains it. If you want to sharpen a knife, you’re going to need a sharpening stone. This WILL create a new edge.

There are all types of sharpening stones to choose varying in size and cost. It’s not necessary to spend a lot of money to achieve a good result. It’s best to find a stone with two different finishes; a coarse side to grind the metal, and a finishing side to complete creating the edge and fine tune the metal.

Begin Sharpening:

Place your sharpening stone on a flat surface on top of a wet cloth to prevent the stone, and the knife from sliding. Make sure that the coarse side is facing you. Place both hands on the bottom of the knife and begin pushing the knife away from you at a 30 degree angle. Each time the knife is pushed across the stone, rotate it so that the other side is sharpened in equal turns. After doing this three of four times, decrease the tilt of the knife by 15 or 20 degrees and repeat the process. Don’t over sharpen your knife during this stage! Each time you drag the knife along the coarse side of the stone, metal is lost, decreasing the overall size of the knife, and curve of the blade. Run your thumb (carefully) perpendicular across the surface of the blade to make sure that you have started to create a new edge. If you find the knife is still dull, simply repeat the first two steps.

Turn over your sharpening stone to the finer side, and slowly drag the knife across the surface pushing it away from you at a 30 degree angle with the blade side of the knife facing you. Decrease the angle, and repeat this process until back portion of the blade is almost touching the sharpening stone. At this point, re-check the blade making sure that you have created a sharp cutting surface. Place a towel on a table and carefully wipe the blade clean.

Sharpening steel

Long and pointed, this thin round rod (also called a butcher’s steel ) is made of extremely hard, high-carbon steel (some of diamond steel or ceramic) and is used to keep a fine edge on sharp knives. The rod is attached to a handle, which usually has a guard to protect the user’s hand from the knife blade. Sharpening steels come in a variety of sizes, the ideal being about 12 inches long. Knives are sharpened by drawing them (while applying slight pressure) across the steel at a 20- to 30-degree angle. Doing this 5 to 6 times on both sides of the blade prior to each use keeps the blade razor-sharp. Dull blades will not be helped by a sharpening steel; they need to be resharpened on a WHETSTONE and then fine-honed on a steel. For maximum efficiency, choose a sharpening steel that is longer than the knife to be sharpened. To prevent metal filings from building up, occasionally clean the steel according to manufacturer’s directions.

Source: epicurious.com

Now that you have a sharp knife, the best way to maintain the edge is by using a sharpening steel. This video illustrates an easy and safe way to maintain an edge on your knives.

How often should you use a steel? Almost every day. Before using your knives, always check to make sure that they are sharp and clean. Using knives that are sharp, and in good condition will help with efficiency, and prevent accidents in the kitchen.

Chef Chuck Kerber

in <b>/var/www/vhosts/cooksandeats.com/httpdocs/wp-content/themes/CooksandEats/sidebar.php</b> on line <b>1</b><br />

/wp-content/themes/CooksandEats/images/side-logo.png)

in <b>/var/www/vhosts/cooksandeats.com/httpdocs/wp-content/themes/CooksandEats/footer.php</b> on line <b>13</b><br />

/wp-content/themes/CooksandEats/images/back-to-top.png)

Just wanted to say that I really like this guide.I find that a honing steel works fine for my needs. There is no compelling reason to supplant it either. The key is to get one that is perfect with the sharpened steel you are honing. This implies the steel must be made of a composite that is as hard or harder than the blade you are honing on it.